Why Computer Diagnostics Are Essential for Truck Maintenance

Truck repair used to be all about experience and intuition—mechanics could diagnose issues just by listening to the engine or feeling the ride. But today’s trucks are high-tech machines, and diagnosing problems has become a whole new ballgame. Thanks to computer diagnostics, mechanics can now read fault codes that point straight to the issue. No more guessing games! This not only saves time but can help prevent costly breakdowns. So, if you’re wondering how this tech is changing how we handle truck repairs, you’re in the right place. Let’s dive into the details!

The Evolution of Truck Repair: From Gut Feelings to Data-Driven Insights

Not so long ago, diagnosing a problem with a truck was as much an art form as a science. You’d rely on a seasoned mechanic who, after years of experience, could “just tell” what was wrong by the sound of the engine or the feel of the ride. While experience is still invaluable, we live in an age where gut feelings aren’t enough. Trucks today are more complex than ever, with intricate electronic systems controlling everything from braking to engine efficiency.

This is where computer diagnostics come into play. Think of modern trucks as high-tech machines with sensors that watch everything. When something’s off, these sensors alert the onboard computer system, which in turn provides a diagnostic code. That code acts like a roadmap for technicians, helping them quickly identify and fix issues.

Gone are the days of trial-and-error fixes or hours of manual inspections. Computer diagnostics turn repair work into a science, saving time and, most importantly, reducing the risk of further damage.

How Computer Diagnostics Work

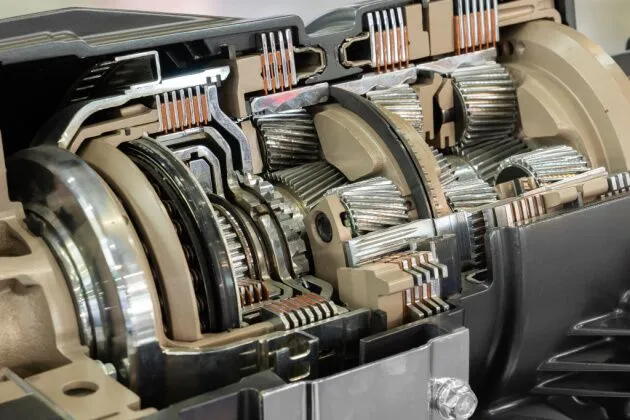

Simply put, a truck’s diagnostic system is a network of sensors feeding data to an onboard computer, commonly referred to as the Electronic Control Module (ECM). These sensors track everything from engine temperature, oil pressure, and brake performance to more sophisticated elements like emissions control and fuel economy.

When a problem arises—say the engine starts overheating or there’s a drop in fuel efficiency—the ECM captures this information and stores a fault code. Mechanics can then use specialized diagnostic tools to read these codes, allowing the truck to “tell” them what’s wrong. This process, often referred to as OBD (On-Board Diagnostics), has been evolving for decades, and now it’s more powerful and accessible than ever.

Some advanced systems can even predict potential issues before they happen. For example, suppose a sensor detects that a component is gradually wearing out. In that case, it’ll send an alert, allowing the truck owner to address the problem before it leads to a costly breakdown.

The Benefits of Computer Diagnostics

a. Speed and Efficiency

Computer diagnostics are great at finding and fixing problems fast. Instead of spending hours trying to track down the source of an issue, mechanics can plug in their diagnostic tool, retrieve the fault code, and get to work right away. This means less time in the shop and more time on the road, which, in the world of trucking, translates to fewer delays and higher profits.

b. Accuracy

Remember when mechanics would try one fix after another, hoping to stumble upon the right solution? Well, those days are fading into the rearview mirror. With computer diagnostics, repairs are more accurate. The system pinpoints the issue directly, reducing the likelihood of misdiagnosis and the need for multiple repairs.

c. Preventative Maintenance

As they say, an ounce of prevention is worth a pound of cure. Modern diagnostic systems don’t just help fix problems; they help prevent them. By constantly monitoring the vehicle’s health, these systems can alert drivers and fleet managers when something is about to go wrong, allowing for preventative maintenance that can save thousands in costly repairs.

d. Cost Savings

It’s no secret that truck repairs can be expensive, especially when parts need to be replaced. Computer diagnostics help cut costs by identifying the malfunctioning part or system, meaning you’re not paying for unnecessary repairs or parts that didn’t need replacing. Plus, by catching problems early, diagnostics can prevent more serious (and costly) issues from developing. In fact, studies have shown that regular use of computer diagnostics can reduce maintenance and repair costs by up to 30% over time, making it a sound investment for any truck owner or fleet manager.

How to Use Computer Diagnostics in Truck Maintenance

a. Regular Scans are Key

One of the best practices for using computer diagnostics is to perform regular system scans. Even if there’s no warning light on the dashboard, running a quick diagnostic check can reveal potential issues before they escalate. Fleet managers can schedule these scans as part of routine maintenance, ensuring that all trucks are operating at peak performance.

b. Understand the Codes

Fault codes are like a different language, and it’s crucial to understand what they’re telling you. While most mechanics are trained in reading these codes, it’s helpful for truck owners or fleet managers to have a basic understanding too. Knowing what’s wrong with your truck helps you have clearer conversations with the mechanic, so everyone’s on the same page.

c. Keep Software Updated

Just like your smartphone or computer, truck diagnostic systems require updates to stay efficient. Manufacturers often release software updates that improve diagnostic accuracy or add new features. Keeping your diagnostic tools up to date ensures that you’re getting the most accurate readings and benefiting from the latest tech advancements.

Challenges of Computer Diagnostics

While computer diagnostics have undeniably revolutionized truck maintenance, they’re not without their challenges. For one, the initial investment in diagnostic tools can be steep. While larger fleets can easily absorb the cost, smaller operations may struggle with the upfront expense. Even though it might cost more initially, the money you’ll save on repairs and maintenance in the long run makes it a good investment.

Another challenge is the complexity of the systems themselves. While the fault codes provide valuable information, interpreting them isn’t always straightforward. Some issues may require specialized knowledge or tools, meaning not all mechanics are equipped to handle every diagnostic result. This creates a learning curve, particularly for older technicians who may not be as familiar with computer systems.

Finally, there’s the issue of reliance. With so much trust placed in diagnostic systems, there’s always the risk of a malfunction within the system itself. Even with advancements, there’s still a chance of false alarms or overlooked issues.

The Future of Truck Repair: Where Do We Go From Here?

Looking ahead, the role of computer diagnostics in truck repair and maintenance will only continue to grow. As trucks become even more tech-driven, with autonomous features and real-time performance monitoring, diagnostics will likely evolve into predictive systems capable of preventing nearly all types of breakdowns before they even happen.

Additionally, more manufacturers are developing cloud-based diagnostic systems, allowing mechanics to access data remotely. Imagine a truck breaking down on the road, and a mechanic can diagnose the issue from miles away using cloud-based tools. This would significantly reduce downtime and get trucks back on the road faster than ever before.

The integration of AI in diagnostics is a game-changer. AI could potentially analyze data from multiple trucks, identifying trends and suggesting preventative maintenance across entire fleets. This could revolutionize fleet management, making it easier to keep trucks in optimal condition while minimizing maintenance costs.

Conclusion

Computer diagnostics have steered truck repair and maintenance into a new era, transforming what was once a manual, time-consuming process into a high-tech, efficient system. By providing accurate, real-time data, these systems enable mechanics and fleet managers to stay ahead of potential problems, reduce downtime, and keep costs in check.

While the technology has challenges, its benefits far outweigh the drawbacks. As diagnostics continue to evolve, we’re moving toward a future where trucks practically maintain themselves, letting us focus on what really matters—keeping goods moving, customers happy, and businesses thriving.

So, the next time your truck’s dashboard lights up, don’t sweat it—just plug in, run a diagnostic, and let the data do the talking. The future of trucking is here, and it’s smarter than ever.

How AP Truck Repair Can Help

At AP Truck Repair, we take full advantage of cutting-edge computer diagnostics to ensure your trucks are operating at peak performance. We specialize in Electrical & Computer Systems, Computer Diagnostics & Repair, and Electrical System Troubleshooting, among other critical truck maintenance services. We aim to minimize your downtime and keep your fleet running smoothly and efficiently. Trust AP Truck Repair for fast, accurate, and reliable service every time your trucks need attention.