Essential Truck Maintenance Tips to Maximize Fleet Uptime

Imagine this: your top-performing truck breaks down in the middle of a critical delivery, bringing your operations to a sudden, screeching halt. Fleet downtime is every operator’s worst nightmare, but the good news is that much of it is preventable. A robust maintenance strategy can drastically reduce the chances of unscheduled repairs and lost revenue. In this blog, we’ll cover essential truck maintenance tips to keep your fleet in top shape, ensuring fewer breakdowns, uptime, and greater profitability.

- Develop a Preventive Maintenance Plan

Preventive maintenance (PM) serves as the foundation of a strong and effective fleet management strategy. This proactive approach involves regularly scheduled inspections, servicing, and repairs to catch potential problems before they escalate into major issues.

Key Elements of a Preventive Maintenance Plan:

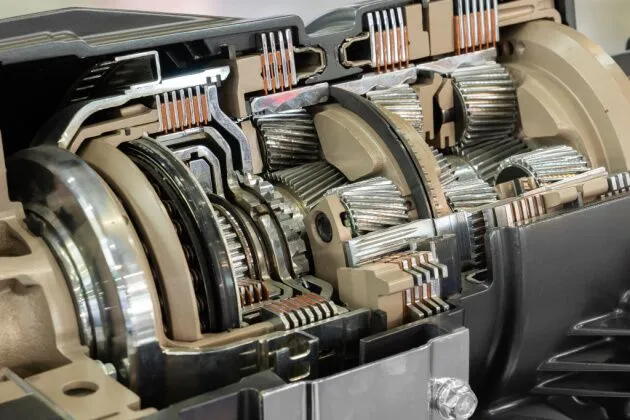

- Routine Inspections: Regularly inspect key vehicle components such as brakes, tires, engine, and transmission. These inspections help identify wear and tear before it leads to breakdowns.

- Fluid Checks and Replacements: Regularly check and replace fluids (oil, transmission fluid, coolant, brake fluid) to prevent engine damage and overheating.

- Scheduled Service Intervals: For oil changes, filter replacements, and other routine services, follow the manufacturer’s recommended intervals.

Adhering to a preventive maintenance schedule lowers the chances of unexpected breakdowns and keeps vehicles running at peak performance. According to the Federal Motor Carrier Safety Administration (FMCSA), fleets that employ preventive maintenance strategies reduce unscheduled roadside repairs by up to 50%.

- Embrace Predictive Maintenance Technology

Predictive maintenance leverages data analytics and telematics to predict when a component will likely fail, allowing fleet managers to address issues before they cause a breakdown. Sensors and diagnostic tools monitor vehicle health in real time, tracking metrics such as engine temperature, tire pressure, and brake wear.

Benefits of Predictive Maintenance:

- Early Issue Detection: Sensors can detect minor changes in vehicle performance that would otherwise go unnoticed, preventing major damage.

- Minimized Downtime: With advanced notice of potential failures, you can schedule repairs at convenient times rather than dealing with unexpected breakdowns.

- Lower Repair Costs: By addressing problems early, you avoid costly repairs that result from neglected maintenance.

Research from Frost & Sullivan suggests that predictive maintenance technologies can reduce overall maintenance costs by up to 30% and improve fleet uptime by 20%. Fleet management software integrated with predictive analytics is becoming increasingly essential for modern fleets looking to maximize uptime and streamline maintenance operations.

- Prioritize Tire Maintenance

Tire maintenance is one of the most crucial factors in keeping trucks roadworthy and minimizing downtime. Improperly maintained tires are a leading cause of roadside breakdowns, which can result in costly delays and repairs.

Key Tire Maintenance Tips:

- Regular Pressure Checks: Under-inflated or overinflated tires wear out faster and can cause blowouts. To extend tire life, maintain the correct tire pressure as per manufacturer specifications.

- Monitor Tread Depth: Ensure that tires meet minimum tread depth requirements. Worn tires reduce traction, especially in adverse weather conditions, and can lead to accidents.

- Tire Alignment and Rotation: Rotate and align tires regularly to promote even wear and prolong their lifespan.

A study by the National Highway Traffic Safety Administration (NHTSA) found that proper tire inflation alone can extend tire life by 10% and improve fuel efficiency by 3%. Keeping tires well-maintained reduces the likelihood of roadside issues and improves overall fleet safety.

- Implement Regular Brake Inspections

Brakes are another critical component that requires vigilant maintenance. Brake failure is one of a fleet’s most dangerous issues, potentially leading to accidents and lengthy downtime.

Brake Maintenance Best Practices:

- Frequent Inspections: Inspect brake pads, rotors, and calipers for wear and damage. Address any signs of wear early to avoid full brake system failure.

- Brake Fluid Checks: Regularly check and top off brake fluid to ensure optimal braking performance.

- Brake Adjustments: Air brake systems on heavy trucks need regular adjustment to maintain effectiveness and prevent excessive wear.

According to FMCSA reports, brake-related issues are responsible for 29% of large truck crashes. By maintaining a strict brake inspection routine, you maximize fleet uptime and prioritize safety for drivers and other road users.

- Ensure Proper Engine Care

The engine is the heart of any truck, and engine problems are often among the most time-consuming and expensive to repair. Regular engine maintenance is critical for minimizing downtime.

Essential Engine Maintenance Tips:

- Regular Oil Changes: Keep up with oil change intervals to prevent engine wear and overheating. Fresh oil lubricates the engine and prevents buildup of sludge.

- Monitor Engine Diagnostics: Use onboard diagnostic systems (OBD) to keep track of engine performance and catch problems early.

- Filter Replacements: Replace fuel, air, and oil filters at the recommended intervals to protect the engine from harmful contaminants.

Ignoring engine maintenance can lead to catastrophic failures that result in days or weeks of downtime. Preventive care ensures that trucks run smoothly and minor issues don’t escalate into major repairs.

- Keep Electrical Systems in Check

The electrical system of a vehicle controls many key functions, from ignition to lighting, and a malfunction can lead to operational delays or complete vehicle shutdowns.

Electrical System Maintenance Tips:

- Battery Checks: Regularly check the battery for corrosion and ensure it holds a proper charge. Replace aging batteries before they fail unexpectedly.

- Alternator and Starter Testing: Ensure that the alternator is charging the battery properly, and the starter is functioning as expected.

- Inspect Wiring: Look for any signs of frayed or damaged wiring, which can cause electrical shorts or system failures.

Electrical system failures are one of the leading causes of breakdowns, and preventive checks ensure that power-related issues are identified and corrected early.

- Leverage Fleet Management Software

Fleet management software plays a vital role in ensuring vehicles stay operational and minimize downtime. It centralizes all maintenance data, schedules, and inspections in one place, making it easy to track service history and plan future maintenance.

Key Features of Fleet Management Software:

- Automated Maintenance Scheduling: Create and manage preventive maintenance schedules based on mileage, engine hours, or specific time intervals.

- Real-Time Vehicle Monitoring: Track the health of every vehicle in your fleet with real-time updates on key performance indicators.

- Maintenance Cost Tracking: Monitor maintenance expenses and make data-driven decisions to reduce costs and optimize operations.

According to a study by the American Trucking Associations (ATA), fleets that utilize fleet management software experience up to 30% reductions in breakdowns and downtime. The efficiency gained from using this technology boosts uptime and enhances overall fleet management.

- Train Drivers on Basic Maintenance

Your drivers are on the front lines of your fleet’s performance. Providing them with basic maintenance training can help catch issues early and prevent breakdowns.

Driver Maintenance Responsibilities:

- Pre-Trip Inspections: Train drivers to conduct thorough pre-trip inspections, covering tires, lights, fluid levels, and brakes.

- Report Issues Immediately: Encourage drivers to report any unusual vehicle behavior (e.g., strange noises and vibrations) as soon as they notice it, enabling timely repairs.

- Proper Driving Habits: Teach drivers the importance of smooth driving techniques (e.g., gentle braking and avoiding hard acceleration) to reduce wear and tear on the vehicle.

Empowering drivers with knowledge and responsibility for vehicle care creates an additional layer of protection against unexpected breakdowns.

- Maintain Detailed Maintenance Records

Detailed maintenance records are critical for tracking the health of each vehicle in your fleet and making informed decisions about repairs and replacements.

Benefits of Keeping Maintenance Records:

- Track Repair Frequency: Identify vehicles that require frequent repairs and assess whether replacement is more cost-effective.

- Compliance with Regulations: Maintain accurate records to comply with federal and state maintenance regulations.

- Warranty Claims: Detailed records help validate warranty claims, saving money on repairs.

By maintaining organized maintenance logs, you can analyze patterns, predict future maintenance needs, and ensure compliance with legal requirements.

Conclusion

Maximizing fleet uptime hinges on a well-structured maintenance plan that prioritizes preventive care, leverages technology, and empowers drivers. By following these essential maintenance tips—ranging from predictive maintenance and tire care to embracing fleet management software—you can reduce costly breakdowns, extend the life of your vehicles, and keep your trucks on the road where they belong.

How Can AP Truck Repair Help?

At AP Truck Repair, we understand that downtime is costly and that keeping your fleet on the road is critical to your business. Whether it’s routine maintenance or urgent repairs, our expert team is ready to help. With specialized services like engine overhauls, computer diagnostics, brake inspections, and custom welding, we cover every aspect of truck and trailer maintenance. Our preventative maintenance plans and fast turnaround times ensure you maximize uptime while minimizing unexpected breakdowns. By teaming up with AP Truck Repair, you can be confident that your fleet will remain in top shape, enabling you to stay focused on the journey ahead.