The Importance of Routine Hydraulic System Maintenance for Heavy Trucks

Every truck driver knows the frustration of unexpected breakdowns. But what if we told you that one of the most common causes—hydraulic system failure—is also one of the most preventable? Hydraulic systems are the unsung heroes of your heavy truck, handling essential tasks like braking and lifting. Unfortunately, they often get overlooked during the hustle and bustle of daily operations. The consequences? Costly repairs, unplanned downtime, and even dangerous accidents.

Why Hydraulic System Maintenance is Critical

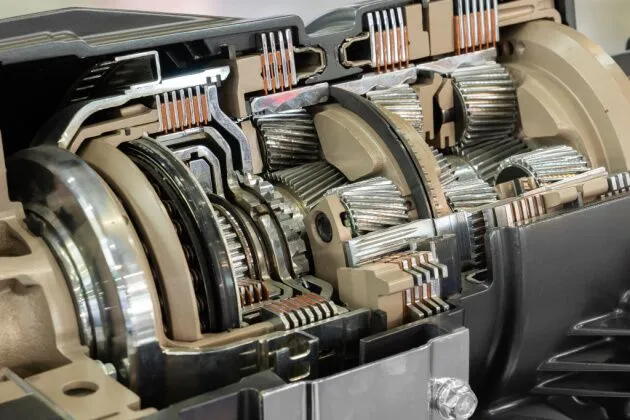

Hydraulic systems in heavy trucks work under extreme pressure, controlling vital functions like braking, lifting, and steering. Over time, these components wear out, fluid levels drop, and contamination can sneak in, causing inefficiencies or even total failure. Regular maintenance ensures these critical systems run smoothly, which directly impacts safety, vehicle performance, and your wallet.

- Avoiding Costly Repairs

Skipping routine hydraulic maintenance can lead to serious mechanical issues. Picture this: your truck’s hydraulic lifting system gives out while unloading cargo. Not only are you facing expensive repair bills, but you could also damage the load and deal with major downtime.

Take the case of a logistics company that had a complete hydraulic failure in one of their heavy-duty trucks because they ignored a simple fluid leak. It ended up costing them $15,000 in repairs, plus a week-long delay in shipments. A quick fix during a routine check could’ve saved them all that trouble.

Hydraulic systems are especially vulnerable to damage from fluid contamination or air getting into the system. Even minor issues, like worn-out seals or old hoses, can snowball into major problems if ignored. Routine inspections help catch these small issues before they turn into big, expensive headaches.

- Reducing Downtime

Nobody likes the dreaded “unscheduled downtime.” It means idle trucks, lost revenue, delayed deliveries, and possibly upset customers. Hydraulic system failures are a top cause of these costly delays.

Preventative maintenance, like checking hydraulic fluid levels and replacing filters, can significantly cut down on the chances of unexpected breakdowns. In fact, some companies have seen a significant drop in downtime by adding hydraulic system checks to their routine. For example, a trucking fleet in the Midwest reduced their annual downtime by 25% after they made hydraulic maintenance a priority.

The time and money saved by avoiding unexpected breakdowns allow your business to run more smoothly, ensuring deliveries are on time and boosting overall productivity.

- Ensuring Safety

The safety of drivers and other road users in the trucking industry depends heavily on the proper functioning of hydraulic systems. A sudden hydraulic failure could lead to dangerous accidents, putting the driver, cargo, and other road users at risk.

Consider a truck hauling heavy machinery that experienced a hydraulic brake failure while going down a steep hill. Thankfully, the driver avoided a disaster, but the truck suffered extensive damage, and the company faced significant liability issues. Regular inspections and maintenance of the hydraulic braking system could have prevented this close call.

Routine maintenance helps keep safety systems in top shape, reducing the chance of accidents and protecting both people and equipment. As hydraulic systems get older, parts can wear out, so regular repairs and replacements are important to prevent accidents and stay safe.

Benefits of Regular Hydraulic Maintenance

Incorporating regular hydraulic system maintenance into a truck fleet’s routine provides several key benefits:

- Prolonged Equipment Life

Heavy trucks are a significant investment, and taking care of their hydraulic systems can extend their lifespan. Properly maintained hydraulic components last longer, reducing the need for early replacements. Over time, this leads to significant cost savings and a better return on investment for fleet owners.

For instance, a mining company with a fleet of dump trucks extended their vehicles’ lifespan by nearly 20% simply by following a routine hydraulic maintenance schedule. This small change saved the company millions of dollars in replacement costs.

- Improved Fuel Efficiency

A well-maintained hydraulic system ensures your truck runs efficiently. Problems like low hydraulic fluid, clogged filters, or leaks can make the engine work harder, using more fuel. Regular maintenance keeps the system in top shape, leading to better fuel economy and lower operating costs.

Many trucking companies have noticed a boost in fuel efficiency after adopting regular hydraulic maintenance schedules. This not only cuts down on costs but also reduces the environmental impact of their fleet—a win-win situation.

- Compliance with Industry Regulations

The trucking industry is regulated by strict rules, and non-compliance can result in hefty fines or even suspension of operations. Many regulations, including those from the Department of Transportation (DOT), require trucks to be in proper working order, especially critical systems like brakes and steering, which depend on hydraulics.

Regular maintenance ensures your trucks meet these regulations by keeping all hydraulic systems in optimal condition. This reduces the risk of fines or the hassle of failing an inspection.

The Real Cost of Neglecting Maintenance

Real-life examples of hydraulic system failures show the true cost of skipping maintenance. One trucking company hauling refrigerated goods experienced a breakdown in their hydraulic steering system, forcing the driver to pull over on the highway. The delay caused their entire load of perishable goods to spoil, resulting in both financial loss and strained relationships with their client.

On the other hand, a food distribution company that prioritized routine maintenance avoided a similar situation. By replacing a faulty hydraulic pump before it failed, they saved themselves from a costly breakdown and kept delivering fresh products on schedule.

How to Develop a Routine Hydraulic Maintenance Program

Creating a routine hydraulic system maintenance program is easier than you might think. Here are actionable steps to get started:

- Set a Regular Schedule: Plan maintenance checks based on mileage or time intervals. Most trucks will benefit from hydraulic system checks every 10,000 to 20,000 miles, depending on use.

- Conduct Thorough Inspections: During every scheduled maintenance, inspect hoses, seals, and fluid levels. Don’t just focus on the obvious components—check for any signs of wear or leaks.

- Replace Filters and Fluids: Keeping the hydraulic fluid clean is essential for the system’s longevity. Regularly replacing filters and using manufacturer-recommended fluids ensures optimal performance.

- Train Your Team: Make sure your drivers and maintenance team are aware of the signs of hydraulic system issues. Training them to identify potential problems can prevent larger issues down the road.

- Keep Detailed Records: Document all maintenance checks, repairs, and part replacements. This ensures accountability and helps spot patterns or recurring issues.

Conclusion

Routine hydraulic system maintenance is essential for ensuring the longevity, efficiency, and safety of heavy trucks. It prevents costly repairs, reduces downtime, improves safety, and helps trucks comply with industry regulations. By incorporating regular checks, replacing fluids and filters, and conducting thorough inspections, fleet owners can keep their trucks on the road and running smoothly.

For truck operators and fleet managers, the investment in regular hydraulic maintenance pays for itself through lower repair costs, fewer breakdowns, and safer vehicles.

How Can AP Truck Repair Help?

At AP Truck Repair, we understand the critical role hydraulic systems play in the performance and safety of your heavy trucks. Our experienced technicians specialize in providing complete hydraulic maintenance and repair solutions to keep your fleet in top condition. From fluid checks and filter replacements to thorough inspections and component repairs, we’ve got you covered. Whether you’re dealing with a minor leak or need a complete hydraulic system overhaul, we use state-of-the-art equipment and industry-best practices to get you back on the road quickly and efficiently.